Ultraviolet Light resides in the area between the visible and X-ray. . The human eye cannot detect most of the UV spectrum, and only a slightly portion is visible and is often referred to violet in color, hence the name Ultraviolet. Many consider this range to be from 10nm to 400nm, but LED companies tend to extend this up to the 430nm wavelength, and sometimes even higher. In reference to UV LED’s for optoelectronic uses, the range is typically 265nm to 430nm, and they are being placed into multiple different packages such as through-hole, surface mount, PLCC’s, high power’s, and COB’s. From there, UV light for LED’s can be broken down even further into three main categories, UV-A, UV-B, UV-C:

| Ultraviolet A | UV-A | 315+ nm |

|---|---|---|

| Ultraviolet A | UV-B | 315-280 nm |

| Ultraviolet A | UV-C | 280-100 nm |

Each Category has its specific use. The higher end of the UV-A has been around for the longest period of time. LED’s in this area have been used in application such a counterfeit detection or validation of official documents. These have been the most readily available UV’s due to them being available for the longest and are usually considered the most price competitive. As you move farther down the UV-A spectrum, the application begins to turn to UV curing. UV LED’s in this range have been used for UV curing in both commercial and industrial materials, ranging from adhesives and inks, to nail salons. UV LED’s have revolutionized the way that these companies use them, as opposed to traditional mercury lamps. These LED’s have reduced the cost ownership and space needed. The UV-B and UV-C applications are relatively new, and they are finding their ways into applications such as disinfecting, DNA analysis, and air purification.

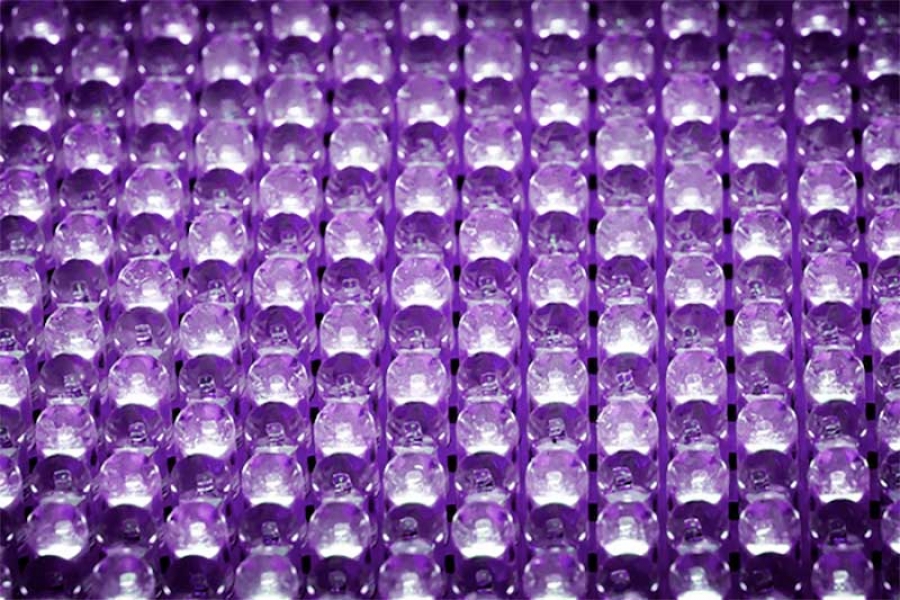

ChromeLED has adapted to this quickly emerging market by providing high quality products that can fit a wide range of applications. One such LED series is our UV LED high power line. CSHD1717UV series is a unique higher power LED that comes in a broad range of wavelengths as well as viewing angles. This package design utilizes QMC (Quartz Micro Lens Cu Substrate) technology, and allows our engineers to package exceptional UV high power into a compact 4.4mm x 4.4mm package. Our high power UV LED comes in multiple viewing angles and power ratings to fit your needs. They can also be placed onto a COB UV array to offer a customized design that will be able to meet typical UV applications, such as curing, coating, printing, sterilization, grow lights, and greenhouse lighting.